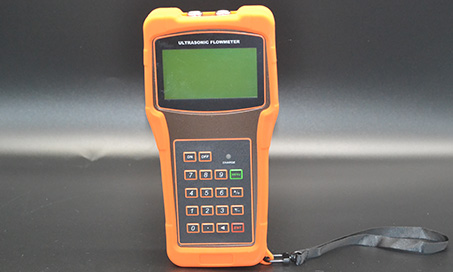

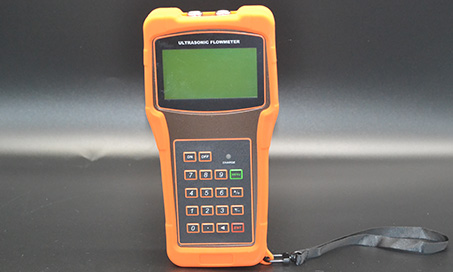

Handheld ultrasonic flow meter

Introduction

Handheld Ultrasonic flow meter incorporates the latest ICs manufactured from the famous semiconductor manufacturers like Philips, Maxim, TI, Win bond, and Xilinx. The hardware features the ease of operation, high accuracy and outstanding reliability, while the software provides a very friendly user interface and much more functions. It employs a patent balanced lower voltage multi-pulse igniting circuit which increases the anti-interference ability magnificently so that the flow meter will work properly even in demanding industrial environments such as those with power frequency transverter working nearby.

Specification

| Linearity | 0.50% |

| Repeatability | 0.20% |

| Accuracy | ±1% of reading at rates>0.2 mps |

| Response Time | 0-999 seconds, user-configurable |

| Velocity | ±32 m/s |

| Pipe Size | DN15mm-6000mm |

| Rate Units | Meter, Feet, Cubic Meter, Liter, Cubic Feet, USA Gallon, Imperial Gallon, Oil Barrel, USA Liquid Barrel, Imperial Liquid Barrel, Million USA Gallons. Users configurable |

| Totalizer | 7-digit totals for net, positive and negative flow respectively |

| Liquid Types | Virtually all liquids |

| Security | Setup values Modification Lockout. Access code needs unlocking |

| Display | 4x8 Chinese characters or 4x16 English letters |

| Communication Interface | RS-232C, baud-rate: from 75 to 57600. Protocol made by the manufacturer and compatible with that of the FUJI ultrasonic flow meter. User protocols can be made on enquiry. |

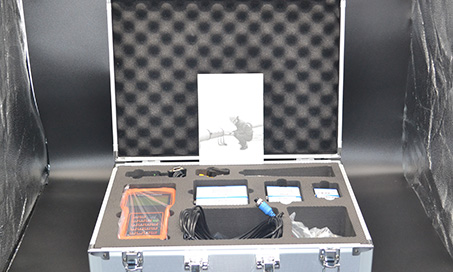

| Transducers | Model M1 for standard, other 3 models for optional |

| Transducer Cord Length | Standard 2x5 meters, optional 2x 10 meters |

| Power Supply | 3 AAA Ni-H built-in batteries. When fully recharged it will last over 10 hours of operation.100V-240VAC for the charger |

| Data Logger | Built-in data logger can store over 2000 lines of data |

| Manual Totalizer | 7-digit press-key-to-go totalizer for calibration |

| Housing Material | ABS |

| Case Size | 100x66x20mm |

| Handset Weight | 514g (1.2 lbs) with batteries |

Feature

-

No obstruction to the flow and zero pressure loss

-

No moving parts and no mechanical wear or tear

-

Easy installation and simplicity of use

-

Easy integration into all kinds of process management systems

-

High accuracy, large turn-down ratio, reliable measurement and fast reaction to changes in process conditions