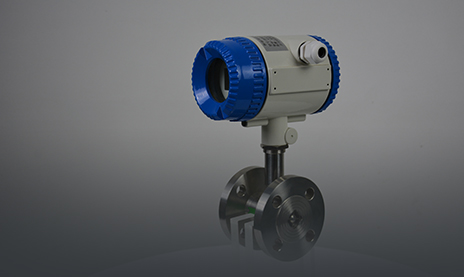

Remote vortex flow meter

Introduction

When an object is inserted into the fluid, the fluid flow is affected, and two series of vortices are alternately separated and released on both sides of the obstacle, and two vortices parallel to each other are formed downstream, called the Karman vortex street. Obstacles are vortex generators, which can be triangular prisms or cylinders.

The swirling direction of the vortex varies depending on the vortex flow. Due to the interaction between the vortices, the vortex flow is generally unstable. But theory and experiments have proved that when the parameter h/l=0.281 (h is the interval of the Karman vortex street, l is the interval of the vortex in the same column), the vortex street is stable, and the separation and release frequency f of the unilateral vortex is equal to The relationship between the fluid velocity v and the width d of the vortex generator (the bottom width in the case of a triangular prism and the diameter in the case of a cylinder) conforms to the following formula:

f=St*v/d

Where: St-Strauhal's coefficient

St is a function of Reynolds number Re. When Re=500~150000, St=0.16 (for triangular prism) and St=0.2 (for cylinder). In fact, the flow rate detected in the industry hardly exceeds this range.

It can be seen from the above formula that the separation frequency f of the vortex is only determined by the ratio of the medium flow rate and the width of the vortex generator, and is not affected by temperature, density, and viscosity. Therefore, by detecting f, the medium flow rate v can be obtained, and by This finds the volume flow of the medium.

Specification

| Measured Medium | Liquid, Gas, Steam |

| Medium Temp | -40℃~+200℃; -40℃~+280℃; 40℃~+350℃ |

| Nominal Pressure | 1.6MPa;2.5MPa;4.0MPa;6.4MPa(Other pressure can be custom,need consult supplier) |

| Accuracy | 1.0%(Flange), 1.5%(Insertion) |

| Measuring range ratio | 1:10(Standard air condition as reference) 1:15(Liquid) |

| Flow Range | Liquid:0.4-7.0m/s; Gas:4.0-60.0m/s; Steam:5.0-70.0m/s |

| Specifications | DN15-DN300(Flange), DN80-DN2000(Insertion), DN15-DN100(Thread), DN15-DN300(Wafer), DN15-DN100(Sanitary) |

| Material | SS304(Standard), SS316(Optional) |

| Pressure Loss Coefficient | Cd≤2.6 |

| Vibration Acceleration Allowed | ≤0.2g |

| IEP ATEX | II 1G Ex ia IIC T5 Ga |

| Ambient Condition | Ambient Temp:-40℃-65℃(Non-explosion-proof site); -20℃-55℃(Explosion-proof site) |

| Relative Humidity:≤85% | |

| Pressure:86kPa-106kPa | |

| Power Supply | 12-24V/DC or 3.6V battery powered |

| Signal Output | Pulse frequency signal2-3000Hz, Low level≤1V, high level≥6V |

| Two-wire system 4-20 signal(isolated output), Load≤500 |

Feature

-

The measuring element of the vortex flow meter is simple in structure, reliable in performance, long in service life and low in maintenance.

-

Matching all flange standards.

-

Short body can be install easily at narrow areas.

-

Vortex flow meter has a wide measuring range, and the range ratio can generally reach 1:10.

-

The volume flow of the vortex flow meter is not affected by thermal parameters such as the pressure, temperature, density or viscosity of the fluid being measured, and generally does not need to be calibrated separately, and can measure the flow of liquid, gas and steam.

-

The vortex flow meter has no moving parts, and there is no throttling part that hinders the flow of fluid, so the pressure loss caused by it is small.

-

The accuracy of vortex is up to 1.0%.