If you want the flowmeter to accurately measure the flow rate, you need to install the flowmeter correctly. The vortex flowmeter also needs to be installed first when measuring, and there will be some requirements during installation. For example, pay attention to this measuring tool when installing, avoid high-frequency equipment as much as possible, or avoid strong power equipment as much as possible. Because during the measurement, if there is high-frequency interference, it may cause the measurement result to be inaccurate. Even high-temperature environments should be avoided as much as possible because high temperature will produce high-frequency radiation, which may also have some influence on the measurement results. Let’s introduce some other requirements during installation.

There is another requirement when the vortex flowmeter is installed, that is, the installation of this measuring tool is divided into upstream and downstream pipelines. The upstream and downstream pipelines must be straight when installing. If it is not guaranteed that there are too many bends in the straightness, it may cause the accuracy of the measurement to be affected to a certain extent. There is also a precaution for installation, that is, to avoid vibration from the outside as much as possible. In particular, try to avoid vibration on the pipeline. If the external environment itself has a vibration, you can consider installing a shock absorption device on the pipeline to reduce the vibration as much as possible. If the vibration is too frequent, it may lead to inaccurate measurement results. Because this measuring tool will artificially create a Karman vortex when measuring, and then measure the frequency of the Karman vortex. If the environment is vibrating, it may cause the measured frequency to be inconsistent with the true frequency.

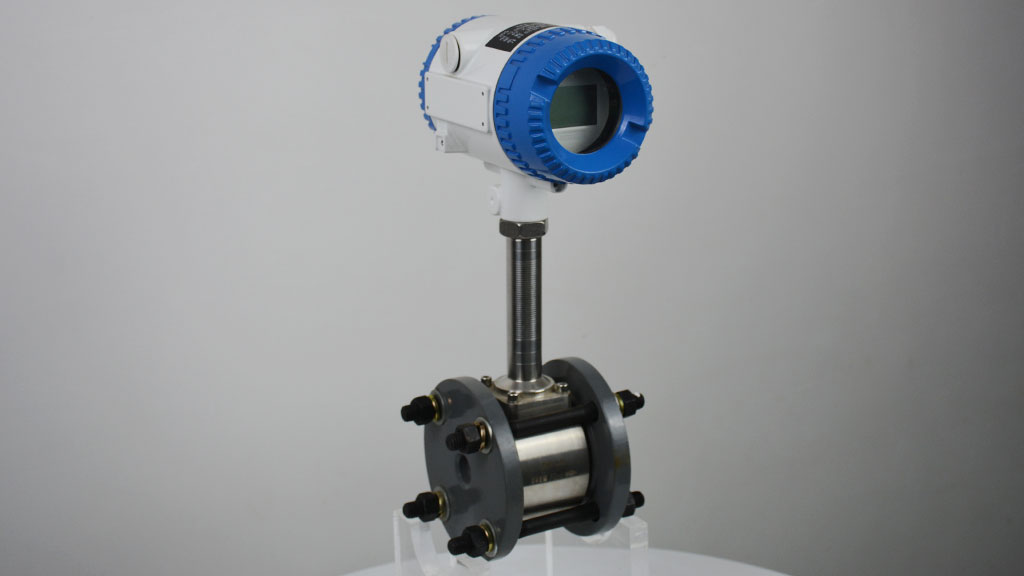

Attention should also be paid to the installation of vortex flowmeters, that is, some problems with the sensor. When this tool is working, sensors are used. Sensors are generally located on vertical pipes. When installing the sensor, pay attention to the correct position of the sensor. In addition, do not use too much force or a lot of vibration when installing the sensor. Because these may cause the sensor to be affected, the sensor is a relatively precise component. Once the accuracy of the sensor drops, it may affect the accuracy of future measurements. Next is the issue of signal shielding. For example, if there is some strong electromagnetic field interference in the surrounding, the surrounding environment is very good with shielding function during installation.